Budget Friendly Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Budget Friendly Lift Maintenance Repair: Maintaining Your Lifts Running Efficiently

Blog Article

Unlocking the Keys to Efficient Lift Services: Expert Insights Revealed

In the world of lift fixing and upkeep, revealing the methodologies that lead to effective and reliable solution belongs to analyzing a complex puzzle. Specialist insights function as the assisting light through the labyrinth of difficulties dealt with by upkeep specialists in the upright transportation market. By diving into the depths of aggressive approaches, fixing strategies, and the constant pursuit of ability enhancement, the path to raising upkeep standards discloses itself. As we embark on this trip to debunk the secrets behind structured lift repair work, a globe of opportunities arises, promising a future where downtime is decreased, safety and security is prioritized, and operational excellence ends up being the norm.

Typical Lift Fixing Challenges

An additional common challenge in lift repairs is the absence of appropriate maintenance documents. Without accurate upkeep documents, repair service specialists may battle to identify concerns effectively or anticipate potential issues. This can result in longer repair service times and boosted prices as technicians work to fix problems without historical data to assist them.

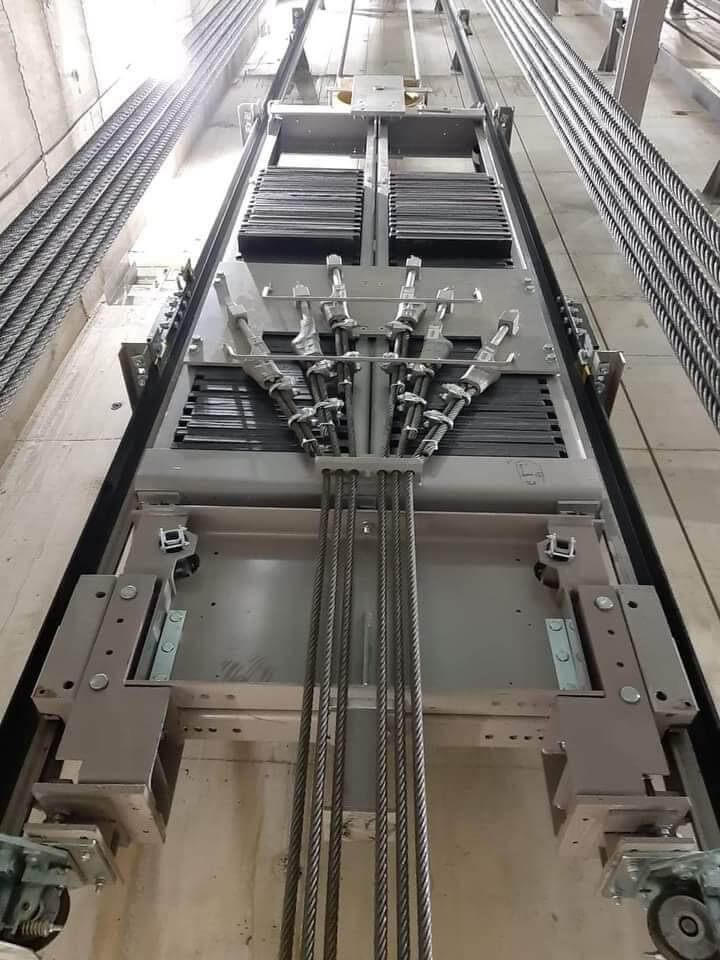

Moreover, access issues within lift shafts can present substantial obstacles throughout fixings. Limited room, unpleasant angles, and complex equipment can make it hard for specialists to get to the necessary elements for repair job, lengthening the overall repair service procedure - Lift Maintenance Repair. By dealing with these common challenges proactively, lift fixing professionals can improve operational effectiveness and guarantee the smooth functioning of upright transport systems

Proactive Upkeep Approaches

Applying aggressive maintenance methods is paramount for guaranteeing the longevity and optimal performance of lift systems. By taking on a positive strategy to upkeep, structure managers and lift maintenance teams can deal with possible problems prior to they intensify right into expensive repair services or downtime. One reliable method is to establish a routine maintenance timetable that consists of detailed inspections, lubrication of relocating parts, and screening of security features.

In addition, buying training programs for maintenance staff can enhance their abilities in identifying possible problems and performing precautionary upkeep jobs successfully - Lift Maintenance Repair. By equipping maintenance teams with the knowledge and devices needed to proactively maintain lift systems, building proprietors can reduce disruptions, extend the lifespan of their lifts, and guarantee a secure and reputable upright transport experience look these up for occupants

Repairing Strategies

Effective fixing methods are important for without delay recognizing and fixing issues with lift systems to reduce downtime and make certain ideal performance. When confronted with a lift malfunction, systematic troubleshooting is important to identify the source precisely. One effective strategy is to begin with an extensive aesthetic examination of the lift components, checking for any type of noticeable indications of wear, imbalance, or damage. In addition, using analysis devices and software application can aid in determining sensor-related or electronic concerns that may not be quickly noticeable.

Enhancing Repair Work Abilities

Enhancing effectiveness in lift system fixings is a basic aspect of making certain optimal performance and reducing functional interruptions. Lift professionals have to consistently work with refining their repair service skills to fulfill the needs of modern-day lift systems. One key technique for boosting repair skills is routine training sessions that concentrate on both theoretical understanding and functional application. These sessions can cover a series of subjects such as new technologies in the sector, fixing complicated concerns, and safety and security procedures. Additionally, specialists can benefit from hands-on experience under the assistance of experienced specialists to improve their analytic abilities and decision-making skills in real-time repair service situations.

Moreover, staying updated with the current developments in lift technology is critical for technicians wanting to enhance their repair abilities. This entails actively looking for information regarding brand-new components, software program updates, and upkeep methods to effectively diagnose and fix concerns. By click to read more spending effort and time into constant knowing and functional experience, lift professionals can dramatically enhance their repair work expertises and add to the reliable performance of lift systems.

Elevating Maintenance Requirements

Boosting maintenance criteria in lift systems is vital for making certain extended operational efficiency and safety. Regular upkeep not just improves the efficiency of lift systems yet additionally decreases the threat of unforeseen malfunctions and makes certain the safety of users. By adhering to strict maintenance methods, lift proprietors and drivers can significantly reduce the likelihood of expensive repair work and downtime.

Carrying out a thorough upkeep routine that consists of routine inspections, lubrication of relocating components, and proactive replacement of worn parts is important. Utilizing sophisticated technologies like IoT sensors and anticipating maintenance software can aid in keeping track of the lift's you can try these out condition in real-time, allowing prompt treatments prior to concerns intensify. In addition, supplying continual training for maintenance staff on the most recent industry requirements and finest methods is crucial for maintaining maintenance excellence.

Furthermore, promoting a society of accountability and attention to detail amongst upkeep teams can better elevate upkeep standards. Urging open communication channels for resolving and reporting maintenance issues quickly can aid in maintaining a high level of lift system integrity. Inevitably, by prioritizing and raising maintenance standards, lift systems can operate efficiently and securely for a prolonged period.

Conclusion

In final thought, reliable lift repair services call for proactive maintenance methods, repairing techniques, and boosted fixing skills. By resolving typical challenges and elevating maintenance criteria, maintenance professionals can successfully make sure the smooth procedure of lifts - Lift Maintenance Repair. Applying these professional insights can result in boosted performance, decreased downtime, and boosted security for both passengers and tools

In the world of lift repair and upkeep, discovering the methods that lead to effective and efficient service is comparable to analyzing a complex puzzle.Another prevalent difficulty in lift repair work is the absence of correct maintenance records. By embracing a proactive approach to upkeep, structure supervisors and lift upkeep groups can attend to prospective concerns before they intensify right into costly repair work or downtime.In conclusion, effective lift repairs call for proactive maintenance techniques, fixing strategies, and boosted repair service skills. By resolving typical difficulties and elevating upkeep requirements, maintenance experts can efficiently make certain the smooth procedure of lifts.

Report this page